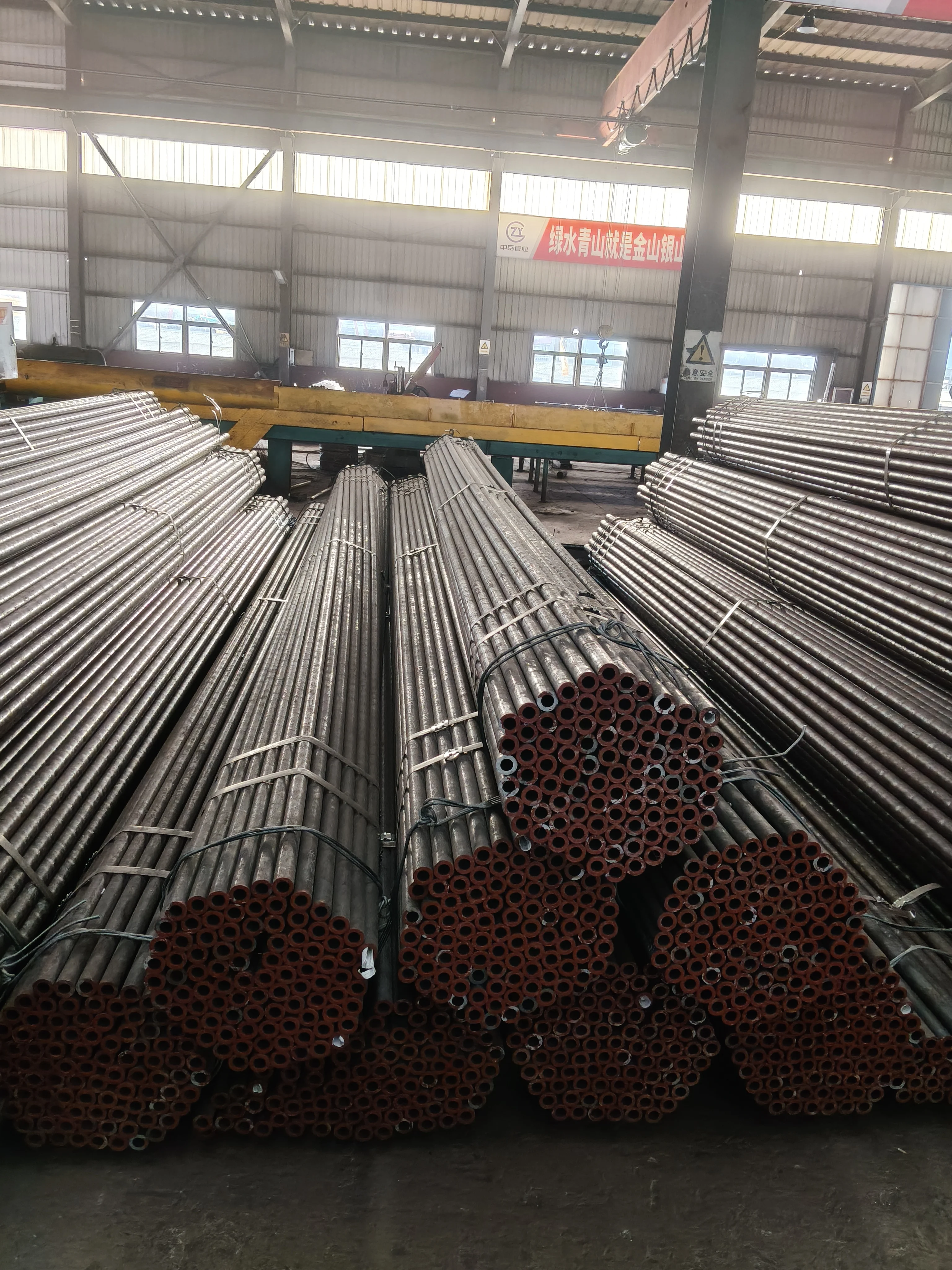

Cold drawn seamless has a much smoother appearance and strength than a regular cutter, not to mention it's more accurate than a cutter, it's special metal its very strong. It serves a number of applications, such as engineering as well as construction, and is also used in both the oil and medical industries as well as many others, It’s very popular amongst the hydraulic and oil industries due to the Zhongyue cold drawn technology, and though maximum profit is sought, as with many other tube materials there are very crucial values: strength, quality, and processibility, so in this article, we’ll take an in-depth look at how this type of Seamless Pipe is made, why it is so invaluable, provided to be subject to quality control.

First, the material that will form the tube is heated and extremely hot. It is then fed into a machine that draws it through sets of dies, or molds, that form it into a tube. This process is known as cold drawing, because even though the material is heated, it’s pulled through the dies for processing at room temperature. This makes the metal stronger and more accurate than other types of Stainless Steel Pipel.

One of the most popular benefits of cold drawn seamless tubing is its strength. That is to say, it has the ability to endure high pressure and temperatures without warping or cracking. This makes it a great material for numerous industries, from oil and gas to automotive to aerospace.

Cold drawn seamless tubes are produced by a process in which a hole is pierced in a solid bar or keen and then the product is drawn through the die. This cold-drawing process improves the alignment of the metal grains, reducing the risk of the tubing failing under pressure. This also serves to increase the tubing strength at elevated temperatures, a critical point in industries where heat is a factor.

A variety of applications employ Zhongyue cold drawn seamless tubing. It is commonly found in high pressure applications in the oil and gas industry. It is also used in the automotive industry in parts requiring precision and strength. For construction applications, cold drawn seamless tubing is used for building construction and architectural applications. For building and construction products, such as building members, columns and floor and roof structures, the Galvanized Pipe required are predominantly end products and are procured under specification or design details specific to particular construction projects.

One of the most compelling reasons is that cold drawn seamless tubing exhibits superior strength and precision. This Zhongyue cold drawing process creates the tubing with a strong thick barrel, which means the tubing will not break under pressure, even where weaker metals such as aluminum would fail. It’s also highly accurate, so it can be relied upon in applications that require precise measurements. In general, cold drawn seamless tubing is an excellent material for use in applications require high precision and high quality.

We hold over 20 industry certifications, including ISO 9001 and CE, and implement a strict quality control system across the entire manufacturing process—from raw materials to finished products—ensuring reliable and compliant steel solutions.

We back our products with a 3- to 12-month warranty and guarantee prompt refunds or replacements for any quality issues, supported by dedicated long-term partnership services.

As a direct manufacturer, we eliminate intermediaries to offer more competitive pricing and quality assurance, while also providing full customization for non-standard sizes and specialized wall thicknesses.

Our 150,000-square-meter high-tech factory is equipped with advanced production lines, including laser cutting machines and CNC flame cutters, and maintains a substantial inventory of nearly 15,000 tons of seamless steel pipes for immediate shipment.

Copyright © Shandong Zhongyue Steel Group Co., Ltd All Rights Reserved - Privacy Policy - Blog