Seamless Steel Pipe Fabrication for Making A Custom Steel Pipe

Steel fabrication is important. Sanitize and more convenient for different types of application. At Zhongyue, we are committed to providing our customers with custom seamless steel tubes that fulfill their unique specifications and requirements to their satisfaction, integrating our latest technology and techniques to achieve superior quality standards.

Knowing the Basics About the Making Process of a Seamless Steel Pipe

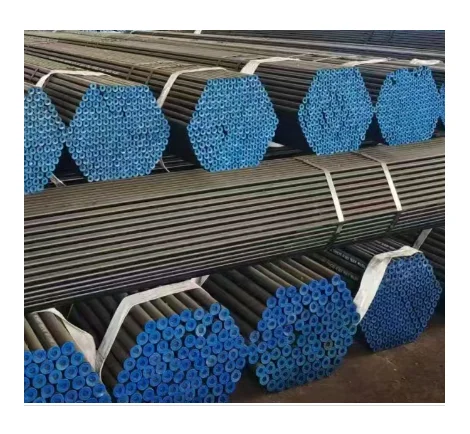

The process begins with a solid, round steel billet. This billet is heated and stretched into a hollow tube. Unlike other pipes, this one can withstand high pressures and it is used in industries like oil and gas, where pressure valves are its advantages. The process may be simple but the control and expertise required to make a good pipe are precise.

Selecting Appropriate Methods for Custom Steel Pipe Applications

The right fabrication method is decisive for custom-made applications. Based on where they are going to be used, we at Zhongyue determine whether to use hot-rolling, cold-drawing or a combination thereof. Hot-rolling is preferable for large, thick pipes, and cold-drawing is appropriate for smaller, more exact ones. Knowing what the project requires is crucial in determining the ideal approach.

Technical Accuracy and Quality Checkpoints

A certain number of steps need to be taken to guarantee the accuracy and quality of seamless steel pipe. Regular inspections and testing are a part of our day-to-day factory life in Zhongyue to nip any problems in the bud. We also utilize state of the art imaging and measuring equipment to verify dimensions and integrity of all pipes. These are the steps to ensure every pipe meets the high standards our customers demand.

Innovative Approaches to Tailored Seamless Steel Pipe Manufacturing

At Zhongyue, we’re constantly looking for new technological advancements to enhance our stainless steel pipe production lines. One way to help is with automation. It follows from the above description that automated systems are capable of controlling their conditions much more uniformly than manual methods and contributing to a higher quality of a pipe. We also test various materials and treatments that will improve the pipes’ properties, such as strength and corrosion resistance.

Improving the Efficiency and Accuracy of the Seamless Steel Pipe Production Process

Enhancement of efficiency and amendment in the accuracy of constructing is a constant goal. We make process improvement as important as introduction of new technologies at Zhongyue. We limit production lead-time by introducing advanced technologies to the factory. Take real-time monitoring systems, for example, we can quickly adjust during fabrication to ensure each pipe is manufactured just perfectly. This saves time and minimizes waste, while bringing the process to be both more efficient and being an eco-friendly alternative.

Table of Contents

- Seamless Steel Pipe Fabrication for Making A Custom Steel Pipe

- Knowing the Basics About the Making Process of a Seamless Steel Pipe

- Selecting Appropriate Methods for Custom Steel Pipe Applications

- Technical Accuracy and Quality Checkpoints

- Innovative Approaches to Tailored Seamless Steel Pipe Manufacturing

- Improving the Efficiency and Accuracy of the Seamless Steel Pipe Production Process