शांडोंग झोंगयुए इस्पात समूह कंपनी, लिमिटेड, चीन के शांडोंग प्रांत में मुख्यालय स्थित है, यह बिना सीमा इस्पात पाइप उत्पादन, इस्पात संरचना निर्माण, और बुद्धिमान लॉजिस्टिक्स सेवाओं में विशेषज्ञता रखने वाली प्रमुख हाई-टेक उद्यम है। इसका क्षेत्रफल 150,000 वर्ग मीटर है और कुल निवेश 176 मिलियन अमेरिकी डॉलर है।

100

उत्पाद सेट

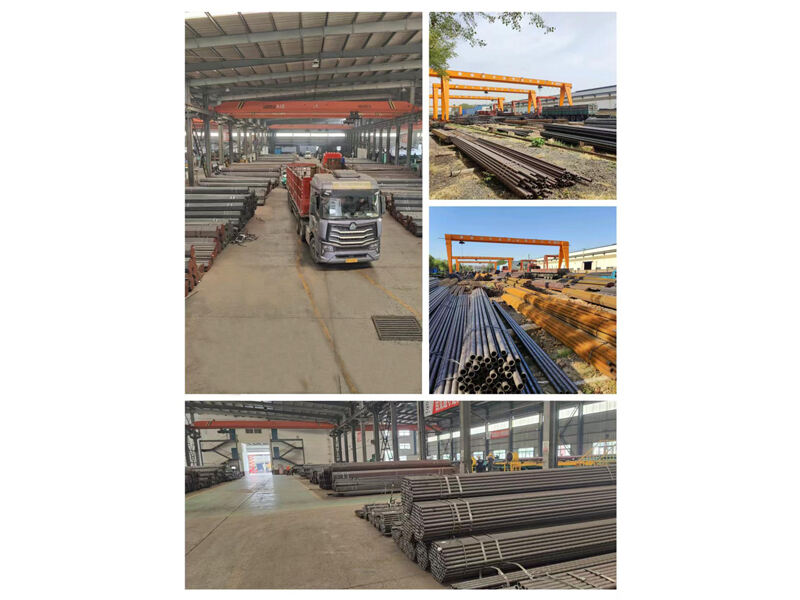

हमारे पास लेजर कटिंग मशीन, शॉट ब्लास्टिंग मशीन और CNC फ्लेम कटिंग मशीन जैसी दर्जनों बड़ी मशीनें हैं, और हम लगभग 600 ग्राहकों की सेवा करते हैं।

हमारे पास बिना सीमा के स्टील पाइप का लगभग 15,000 टन का स्टॉक है और हम उन्हें सीधे भेज सकते हैं।

सीमेंटल स्टील पाइप और स्टील संरचना निर्माण की पूरे प्रक्रिया पर केंद्रित होते हुए, कच्चे माल के नियंत्रण से तकनीकी उत्पाद पहुंचाने तक, एक कठोर गुणवत्ता प्रबंधन प्रणाली स्थापित की जाती है। मानकीकृत संचालन और विशिष्ट परीक्षण विधियों के माध्यम से, स्थिर और विश्वसनीय उत्पाद गुणवत्ता का पालन किया जाता है, परियोजना के लिए एक मजबूत गुणवत्ता आधार बनाते हुए।

कॉपीराइट © शेंडॉनग झोंगयुए स्टील ग्रुप कंपनी लिमिटेड सर्वाधिकार सुरक्षित - गोपनीयता नीति-ब्लॉग