Large-Space Modern Steel Workshop Column-Free Design for Unobstructed Industrial Operations

- Overview

- Recommended Products

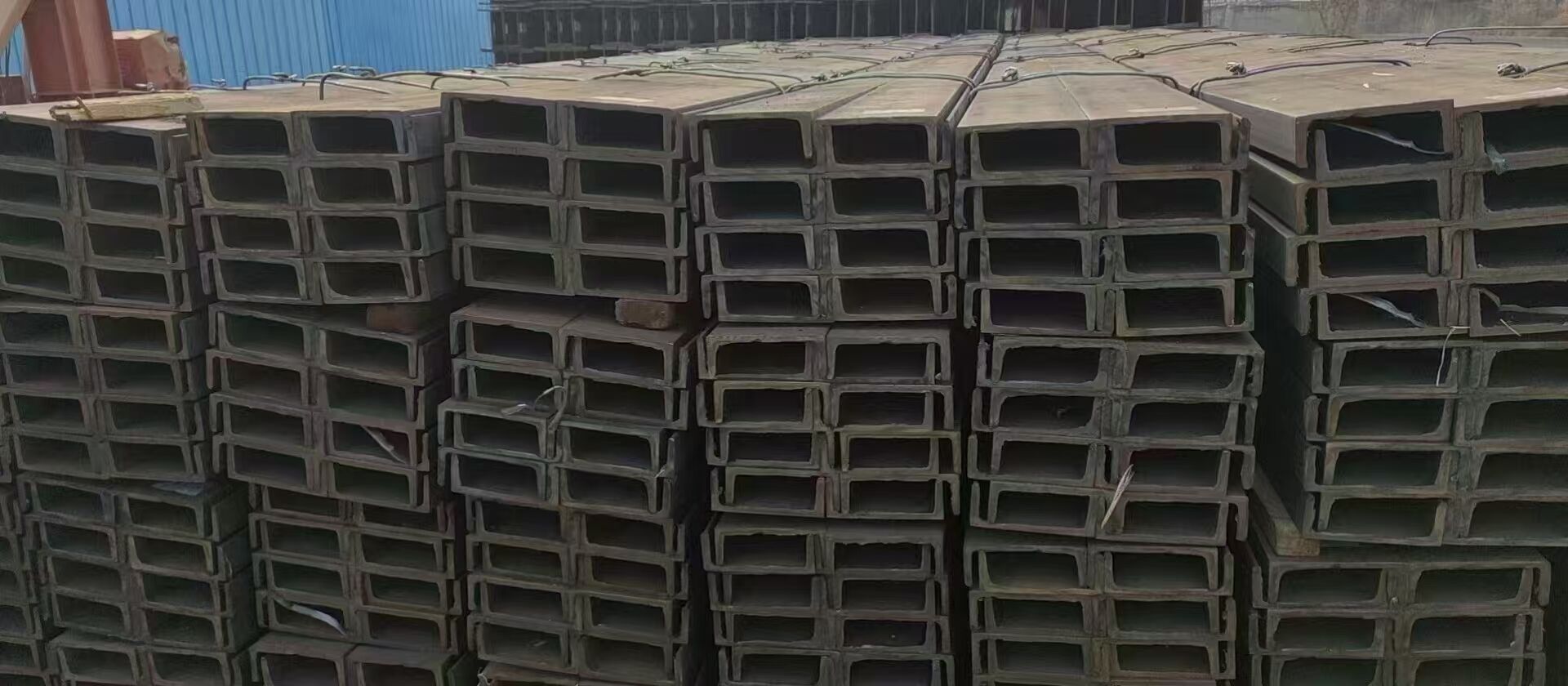

The Zhongyue Large-Space Modern Steel Workshop offers a cutting-edge solution for industrial operations in need of a spacious and unobstructed workspace. This workshop features a column-free design, allowing for maximum flexibility and efficiency in conducting various tasks.

Constructed with high-quality steel, the Zhongyue workshop is built to last and withstand the rigors of daily use. The modern design not only enhances the aesthetics of the workspace but also ensures a safe and secure environment for workers.

With its large space, this workshop provides ample room for storing equipment, machinery, and raw materials. The unobstructed layout allows for easy movement of goods and personnel, streamlining operations and improving productivity.

Whether used for manufacturing, warehousing, or other industrial purposes, the Zhongyue Large-Space Modern Steel Workshop is versatile and adaptable to meet the specific needs of businesses. The open floor plan offers endless possibilities for customization, allowing for the installation of specialized equipment or machinery to optimize workflow.

In addition to its functionality, the workshop is also designed with the environment in mind. The steel construction is eco-friendly and sustainable, making it a responsible choice for businesses looking to reduce their carbon footprint.

The durability and reliability of the Zhongyue workshop make it a wise investment for any industrial operation. Its sturdy construction ensures long-term performance and minimal maintenance, saving businesses time and money in the long run.

The Zhongyue Large-Space Modern Steel Workshop is the ideal choice for businesses seeking a versatile, efficient, and sustainable workspace. With its column-free design and spacious layout, this workshop provides the perfect environment for unobstructed industrial operations. Trust Zhongyue for a top-of-the-line solution to your industrial workspace needs

Dimension Range

|

Length |

1000-15000mm - customizable |

|

Web Thickness |

6-32mm |

||

Wing thickness |

6-40mm |

||

Height |

200-1200mm |

||

Surface Treatment |

Painted, galvanized, or customized per requirements |

||

Main Components |

Foundation |

Cement & steel foundation bolts |

|

Main Frame |

H-beam/I-beam |

||

Steel Grade |

Q235B, SM490, SS400, Q345B, or buyer-specified |

||

Purlins |

C120~C320/Z100~Z20 |

||

Bracing |

X-shaped or other types - angle/round tubes |

||

Fasteners |

Common & high-strength bolts |

||

Sheet Thickness |

0.5mm/0.6mm galvanized steel |

||

Applications |

Workshops, warehouses, factory buildings |

||

Steel web frame structures |

|||

Steel H-columns & H-beam frameworks |

|||

Door frame products |

|||

High-rise construction projects |

|||

Other steel structural buildings |

|||

Product Advantages |

Lower cost & better quality |

||

High safety performance |

|||

Easy assembly/disassembly |

|||

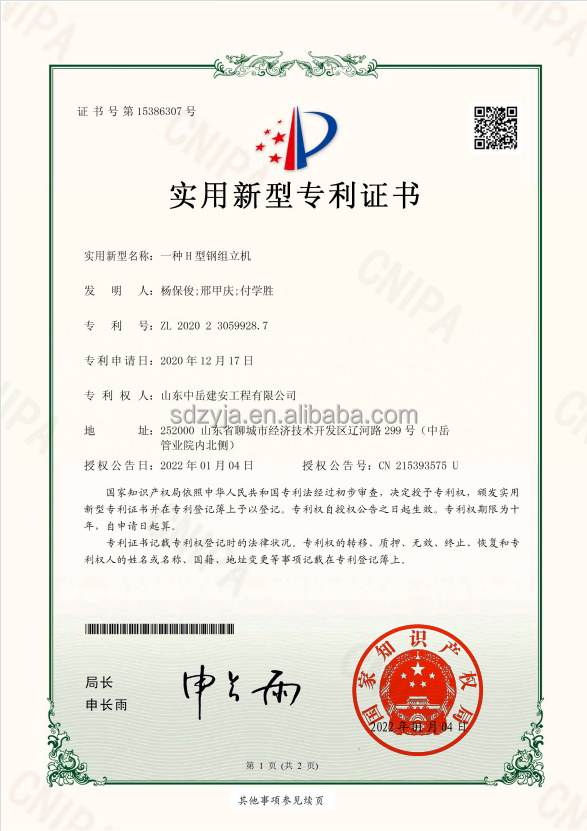

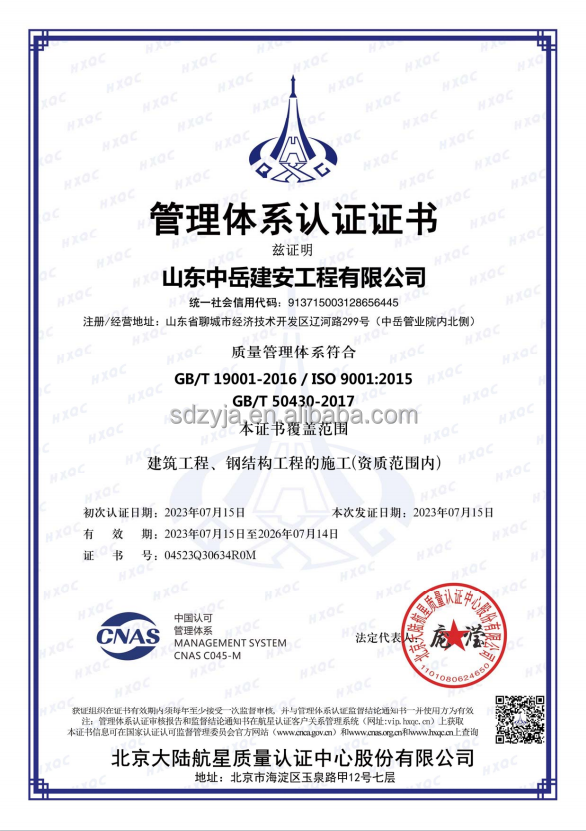

ISO 9001-certified quality system |

|||

Installation guidance by experienced engineers |

|||

Environmentally friendly |

|||

Packaging |

Standard export waterproof packaging (suitable for all transportation) or customized |

||

Steel Structure Division

Equipped with two advanced production lines and state-of-the-art processing equipment, the group produces over 35,000 tons of steel structures annually. Products are widely applied in:

* Industrial plants and storage facilities

* Bridges and super high-rise buildings

* Modular prefabricated buildings

* New energy infrastructure

* Heavy machinery frames

Seamless Steel Pipe DivisionFeaturing four hot-rolling production lines, the group manufactures 200,000 tons of seamless steel pipes annually. Key products include:

* Corrosion-resistant and pressure-resistant oil well pipes

* High-pressure boiler pipes

* Hydraulic prop pipes

* High-precision mechanical pipes

* Structural pipes

With diameters ranging from 38–219 mm and wall thicknesses of 4–22 mm, these pipes serve industries such as petroleum, chemical engineering, coal, machinery, hydraulic props, and automotive

Competitive AdvantagesBy integrating German precision with the scale advantages of Chinese industry, the group delivers cost-effective solutions without compromising quality. Its vertically integrated supply chain—from raw material procurement to global delivery—ensures consistent quality, prompt response, and 24/7 technical

* Payment Methods: Telegraphic Transfer (TT) and Letter of Credit (L/C) are accepted. TT is preferred.

* Payment Terms:

* 30% deposit paid before production commences;

* 70% balance paid via TT before shipment.2. What is the delivery time

* Standard Lead Time: 15–40 days (varies based on order quantity).

* Expedited Service: Available upon request (additional fees may apply).

3. How are products packaged

* Standard Packaging: Export-grade packaging (moisture-proof, shock-resistant, damage-proof).

* Custom Packaging: Customized solutions are available, with additional costs to be covered by the buyer.

4. How to install products after delivery

* Technical Support: * Detailed installation diagrams and operation manuals provided;

* On-site technical assistance available upon request (buyer responsible for visa fees, airfare,

accommodation, and labor costs).